With BySoft 7 and Mietrak, Tilley & Patton Ltd facilitate a digitally networked manufacturing environment. From incoming order to the finished part, high-performance software supports data flows between machines and processes, ensuring seamless and efficient workflow throughout our facility.

Let's Connect:

Laser Cutting:

Our precision fibre laser cutting system offers speed and flexibility. We can process a wide range of materials and thicknesses, from steel and stainless steel to aluminium and non-ferrous metals such as brass and copper. An intelligent automated loading and unloading system further enhances our ability to handle high-capacity requirements with speed and efficiency.

Punching:

Our high-speed CNC turret punch presses offer high energy efficiency and exceptional repeatable accuracy for punching and forming. With our large turret capacity and an extensive library of indexable multitools, we cater for all high production punching, batch processing and architectural requirements.

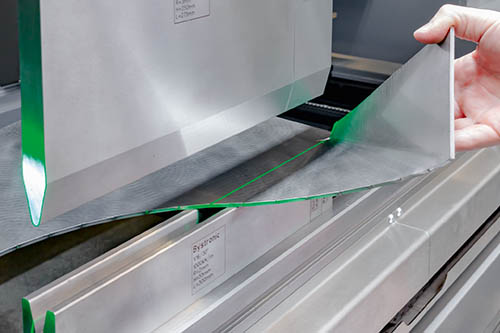

Folding and Rolling:

Tilley & Patton Ltd offer a wide range of precision CNC folding solutions. Our extensive tooling and equipment packages enable first class bending results, repetition, accuracy, and fully automatic dynamic crowning for all production and bespoke manufacturing. In addition, we offer fast and accurate plate rolling capability. We can process a wide range of sheet materials, sizes and thicknesses for a variety of applications and end uses.

Deburring and Edge Rounding:

To ensure the best quality result for our manufactured items, we can provide deburring and edge rounding to ensure a smooth finish. Our machine can process stainless steel, steel, aluminum or non-ferrous metal workpieces on both sides as well as edge rounding of workpieces in one operation, ensuring consistency as well as efficiency in our workflow.

Welding, Spot-Welding and Assembly:

We combine a trade qualified team with the latest MIG, TIG and Arc equipment to weld materials ranging from thin gauge sheet to thicker plate. In addition, we offer multiple spot-welding stations with the ability to handle a wide variety of materials and thicknesses. Full assembly service available for volume and small batch production requirements.

Collaborative Environment & Partnerships:

From rapid prototyping to full production runs, Tilley & Patton Ltd can assist with decades of hands-on experience and the best of today’s technology. Our technology centre is equipped with the latest software (AutoCAD and SolidWorks) allowing seamless development from concept to reality. We partner with ISO approved partners to provide the best plating and finishing services.